The Market

The urinary catheter market is worth

~$1bn p.a. and within this market some sectors are increasing in value by more

than 10% CAGR. The insertion of any catheter into the body is a potential route

for infection by the very nature that they are in contact with the outside

world; additionally urinary catheters carry a concomitant risk to encrustation

leading to blockage and catheter associated urinary tract infection (CAUTI)

which increases significantly with the indwelling time of the catheter (+5% per

day). CAUTI accounts for >40% of all institutionally acquired infections.

The Foley catheter was first introduced

in the mid-1930s and is the most common form of urinary catheter in use today.

It has undergone a series of incremental changes resulting in the modern

version, predominantly through a change in materials and lubrication

technologies for patient comfort.

The Foley catheter however is

implicated in 80% of the CAUTIs noted above.

Current solutions in catheter technology

provide for antibiotic impregnated devices and silver ion coating technologies.

These devices have been widely adopted, but the data available now do not fully

support the claims associated with these technologies and bacterial

antimicrobial resistance to these approaches has been noted as a potential

problem due to the selective pressure induced by the nature of their action.

There are significant market drivers to provide improved solutions to CAUTI, the

treatment of which adds a huge burden on the health service ($1,000 per

patient). These costs are no longer reimbursable under the Medicare program in

the US.

Technical

Information

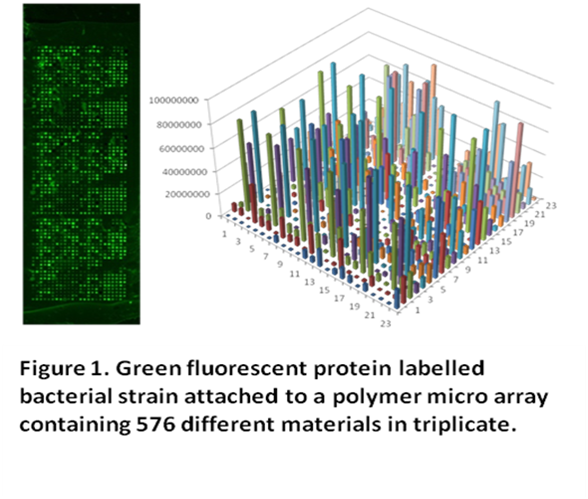

We are producing materials that have

intrinsic anti-adherence properties on which bacteria find it difficult to

attach and grow. In screening against a range of pathogens (uropathogenic

Escherichia coli, Pseudomonas aeruginosa and

Staphylococcus aureus) the large number of polymers screened have

demonstrated a wide range of bacterial adherence characteristics (Figure 1).

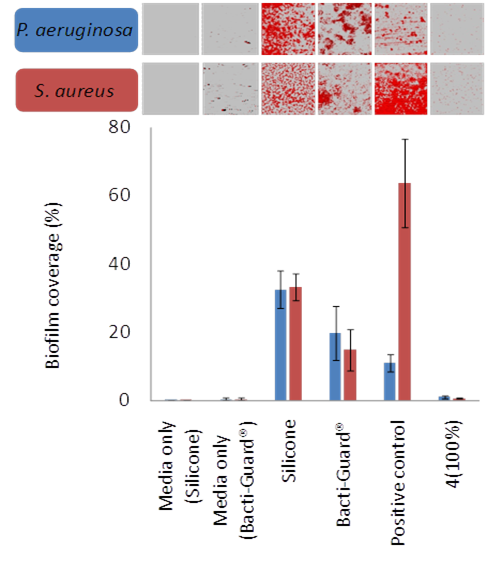

A total of 22 candidate polymers have

been selected that show significant reduction in bacterial adherence. These

polymers are the subject of scale-up protocols indicating significant improved

performance against uncoated silicone catheters and the market leading anti

infective coating Bactiguard® (Figure 2). Candidate polymers are being further

characterised and evaluated for their suitability in production and/or as

coating technologies.

Figure 2. Comparison of bacterial coverage for PA

and SA on a hit polymer (4 100%), uncoated silicone catheter, a commercial

catheter (Bacti-Guard) and a positive control with the negative media-only

controls.

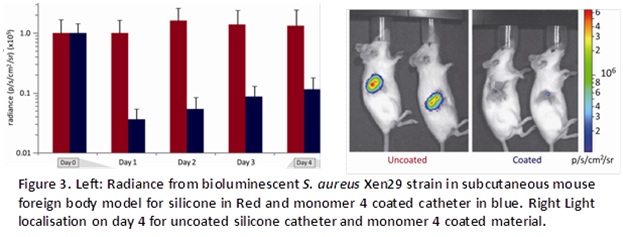

In vitro studies have demonstrated the

rationale and predictable antibacterial properties of the candidate polymers.

Scale-up onto silicone catheters have resulted in excellent in vivo results from

a murine subcutaneous foreign body model shown in Fig 3.

This illustrates clearance of a

bacterial inoculate by the host immune defence system when placed in

the lead polymer in vivo, compared to the silicone catheter where bacteria

adhere, form biofilm and persist over the 4 day period of the experiment.

We are undertaking a 4 year program to

evaluate this polymer coating technology and aim to license the technology

to key businesses that provide urinary catheters throughout the world

markets. We are not seeking to make incremental changes in the

performance of these devices, rather we are gearing up to provide step

change improvements over the existing competition.

Our planned route to market for the

technology is through the catheter market via a licensing deal with an

established supplier of urinary catheters prior to diversification into other

applications for the technology.

Patents

The technology employed is

protected by two patent applications which are being prosecuted internationally:

-Polymer arrays for biofilm

adhesion testing, publication number WO

2009/019519, 2007.

(http://uon.technologypublisher.com/technology/8194)

-Novel polymers which resist

bacterial attachment, UK Patent Application no: 1107416.8, 2011.